Our testing center can make structure test, electronic test, material test and optics test.ISO17025 is in the process.

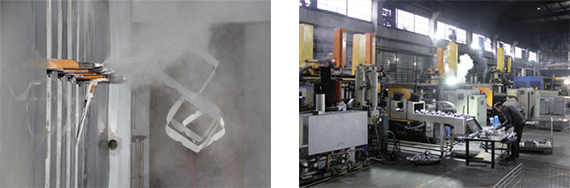

Structure test: IP class test, IK class test, wind pressure test and vibration test.

Electronic test: EMC test, surge test, and high&low voltage test.

Material test: salt spray test, coating layer thickness measurement, hardness test, and magnetic particle test .

Optics test: Integrating Sphere and GO-R5000 full-field speed goniophotometer.